Who are implementing the Porthos project?

The Porthos project is divided into a number of phases, some parallel and some succeeding each other. The construction of the land and sea pipeline transport network, the construction of the compressor station and cooling water intake building and the modification of the platform have been put out to European tender. The overview below shows which main contractors have been contracted for the various construction works:

| Work | Main contractor(s) |

| Onshore pipeline | DENYS NV and LMR Drilling GmbH |

| Compressor station | Bonatti Società per Azioni |

| Cooling water intake building | G. van der Ven B.V. Aannemingsbedrijf |

| Platform | TAQA |

| Wells | TAQA |

| Offshore pipeline | Allseas |

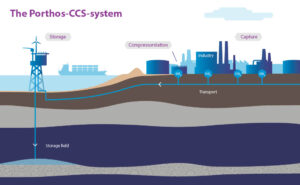

Why is this CO2 project being developed?

Porthos offers companies the opportunity to reduce their CO2 emissions in the period when alternative, sustainable techniques are not yet sufficiently developed. This enables companies to contribute to the Netherlands’ climate objectives and to the energy transition

CCS (Carbon Capture and Storage) is a relatively cheap measure that can already significantly reduce CO2 emissions in the short term. The long-term goal remains the sustainability of industrial production processes.

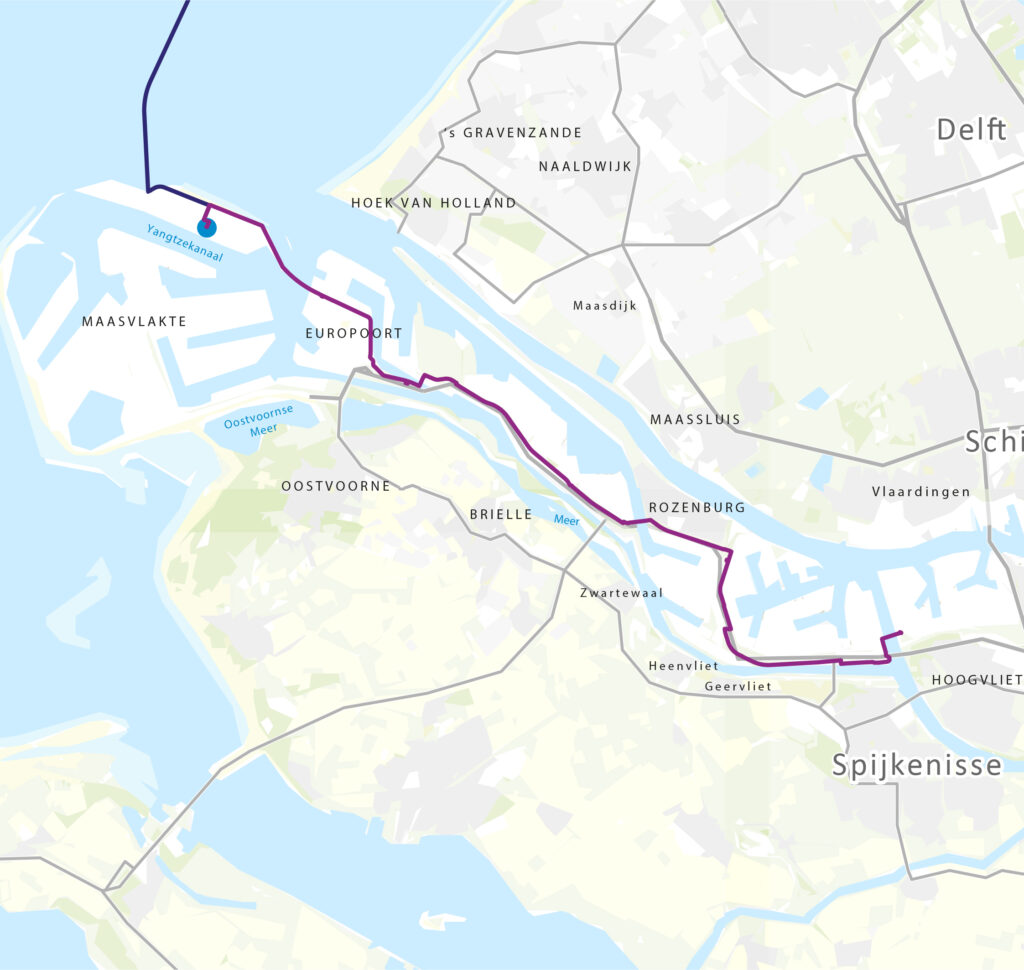

Where will the CO2 pipeline be located?

The onshore pipeline will be located in the existing pipeline strip along the A15, via Botlek-Vondelingenplaat to the Maasvlakte. The onshore pipeline is about 30 kilometres long.

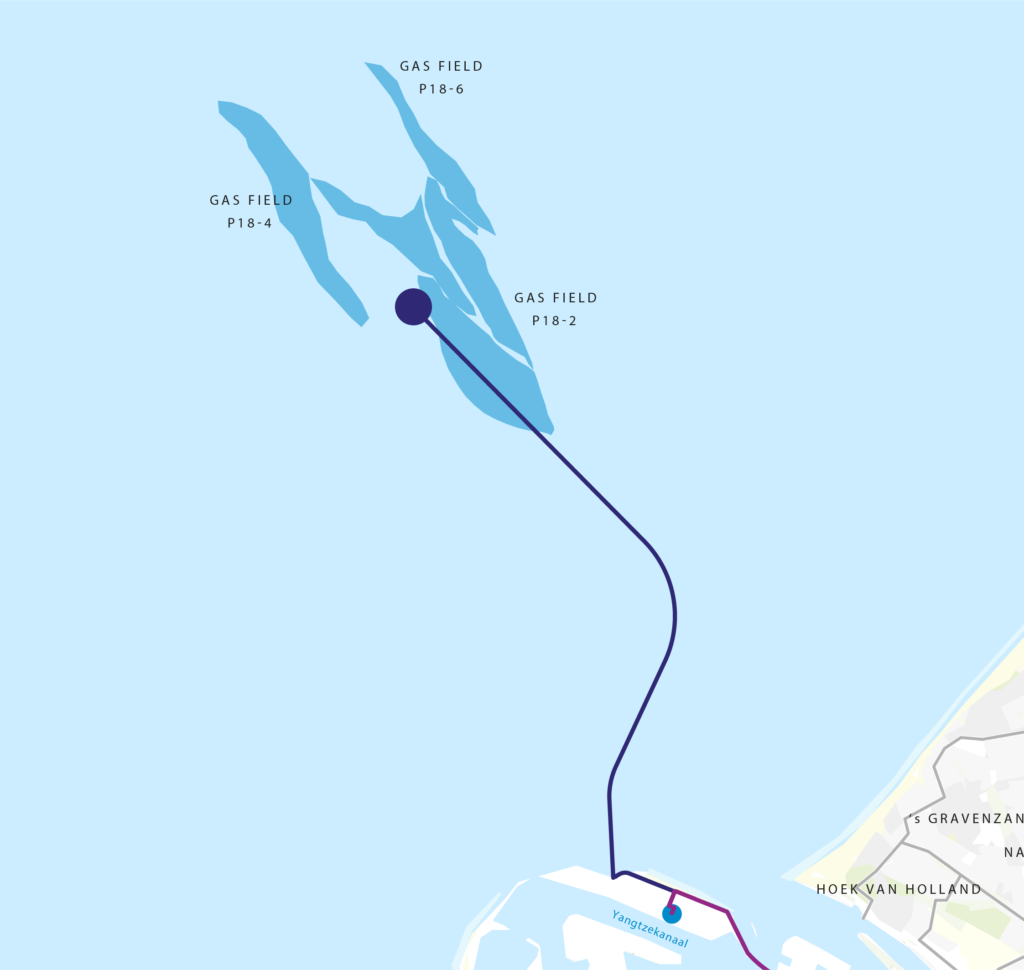

Via a compressor station, a pipeline then goes under the North Sea bed to a platform about 20 kilometres off the coast. From there, the CO2 goes to depleted gas fields over three kilometres below the North Sea bed.

In which fields will the CO2 be stored? Who owns those fields?

From the platform, CO2 will be permanently stored in depleted gas fields three to four kilometres below the North Sea floor. Porthos focuses on storing CO2 in the former gas fields P18-2 and P18-4.

TAQA has extracted gas from these fields and the fields are available for storage. From the existing platform of P18A, operated by TAQA, Porthos will inject the CO2 into the depleted gas field.

When will the storage of CO2 start?

The final investment decision for Porthos was made in October 2023. Construction of the Porthos infrastructure started in early 2024. The system is expected to be operational during 2026.

Which parties will supply the CO2?

In December 2021, Air Liquide, Air Products, ExxonMobil and Shell signed final contracts with Porthos for transport and storage of CO2. These parties are located close to each other in the port of Rotterdam, which offers infrastructure advantages.

Together, the companies will capture and deliver 2.5 million tonnes of CO2 annually from their Rotterdam plants to the Porthos infrastructure from 2026. Over a period of 15 years, this will total around 37 million tonnes, which will remain permanently stored under the North Sea.

Click here for more information about the commercial process.

How does Porthos differ from previous CO2 transport and storage initiatives?

Elsewhere in the world, experience with CCS has been around for more than 30 years. What makes Porthos particularly special is that it is one of the first CCS projects to focus on the permanent storage of CO2 from multiple companies, using an open access approach. The system is set up as a kind of utility infrastructure that can also be used by different companies.

Unlike the ROAD project (Rotterdam Storage and Capture Demonstration Project), Porthos focuses on industry for which there are no sustainable alternatives for the time being. Another important difference is that in the Porthos project, storage is not on land under existing construction, but under the North Sea.

Is the Porthos project safe for the environment?

During the preparation of the Porthos project, extensive and detailed research was carried out on various environmental aspects and impacts of the transport network. The results were described in the environmental impact report (EIR). Royal HaskoningDHV wrote a public summary of the EIR on the Porthos infrastructure, which is publicly available.

The effects in the construction and use phase are zero or very limited. In addition, we work with sustainable (electric) materials wherever possible during network construction.

Construction phase

During the onshore construction of the Porthos pipeline, the soil quality actually improves because any soil contamination is remediated. During construction on land, at sea and the realisation of the compressor station, nitrogen is released from traffic, working equipment and shipping movements. Measures will be taken to limit the amount of nitrogen released. The Porthos infrastructure will not result in damage to the natural features of Natura 2000 areas. The Nature Conservation Act will be carefully taken into account throughout the entire realisation process. As the infrastructure will be constructed almost entirely underground, there will be no landscape changes. The flora and fauna will therefore only be slightly disturbed for a very short time at most, during the implementation work at the site. Underwater drilling, piping and dredging will temporarily cause some noise nuisance for marine animals. There are sufficient escape routes for these animals and sufficient suitable habitat is available.

Operation phase

The pipeline has no environmental impact in the use phase. To ensure optimum safety, no houses can be built in the so-called risk contour. This also applies to the compressor station: from a safety perspective, no houses can be built in the immediate vicinity here either.

Final phase

After the 15-year use phase, the pipelines are shut off and left in the ground. The gathering pipeline and compressor station has more capacity than Porthos itself uses. There is therefore room for subsequent CCS projects. When further use is no longer possible, the compressor station will be removed, with environmental impacts similar to those in the construction phase.

Is the Porthos project safe for its surroundings?

Safety is one of the most important preconditions for Porthos. , both for the people involved in the work on the route and for local residents and surrounding businesses. Both during the construction of the transport network of great importance to local residents and surrounding companies and also in the operational phase; once the system is in use. An environmental impact report (EIA) was prepared in June 2020. The Ministry of the Interior and Kingdom Relations (BZK) is the initiator for the plan part of the EIA and Porthos for the project part. Royal HaskoningDHV wrote a public summary of the MER on Porthos infrastructure, which is publicly available.

Construction phase

Porthos’ land pipeline will be located in the existing pipeline strip along the A15, via Botlek-Vondelingenplaat to the Maasvlakte. The land pipeline is approximately 30 kilometres long. Working in the pipeline strip does require a great deal of coordination.

Strict guidelines and fixed procedures apply to work in the pipeline strip. Our contractors must work according to the rules laid down in the City of Rotterdam’s ‘Pipes Manual’. This manual is not a guideline but has legal status.

Before starting work outside, there was a lot of consultation with the managers and owners of the existing cables and pipelines in the project area. A logical consequence of the fact that transport in the port of Rotterdam is probably even busier underground than above ground. The consequences of disruptions in the cable and pipeline strip are far-reaching; product loss, process downtime and even the creation of dangerous situations when factory processes stagnate. The role of pipeline owners and operators is great for this reason. By working together according to fixed procedures, we ensure the safe location and use of the pipelines.

Operation phase

As soon as the Porthos system goes into production, CO2 gas flows through the pipeline system. The pipeline, compressor station, platform and wells are designed with all relevant safety standards to minimise the likelihood of any unforeseen events. CO2 is neither explosive nor flammable. There is a very low safety risk in case of leakage into the Porthos infrastructure. If so much CO2 is released that it displaces oxygen from the air as a CO2 cloud AND there is long-term exposure to a very high CO2 concentration, this could be dangerous to human and animal health.

Leaks in the land pipeline could be caused by work in the pipeline strip, damaging the pipeline. The pipeline is continuously monitored. If leakage occurs, it is quickly reported and resolved so that the volume of CO2 released is limited. The pipeline can also be affected by corrosion. The chance of this happening is small because the pipeline is protected against corrosion by a protection system and a coating around the pipeline. Especially for Rozenburg, a response plan is being developed in cooperation with the Rotterdam Safety Region for all possible scenarios.

The compressor station and platform on the North Sea are at a great distance from buildings, so there are only risks for the company’s own personnel. Personnel are trained in how to deal with this and provided with the necessary safety equipment.

If the pipeline is damaged underwater and a large leak occurs, the effluent CO2 will immediately mix strongly with the water. As a result, a gradual flow of CO2 will rise to the surface. This may affect passing vessels. The risks are similar to existing risks as there are many gas pipelines under waterways.

The CO2 will be stored at a depth of 3 to 4 kilometres under the North Sea. The wells, so-called P18 reservoirs are located in a rock layer that is millions of years old. The natural gas in these wells that was previously extracted is in sealed sections. The injection of CO2 will increase pressure in the reservoirs, but strict control measures ensure safe storage. There is also concern about possible ground rise and risks of earthquakes, although the likelihood of this is small. The risk of CO2 leakage is considered negligible; to further mitigate the risks, well walls are periodically checked and there are control measures for well walls and fractures.

In the first 15 years after the Porthos system is operational, the gas field is filled by Porthos itself and continuously monitored so that any leakage is quickly recognised. The State Supervision of Mines monitors the monitoring. After removal of the wells and platform, direct monitoring is no longer possible. By then, the reservoirs have been found to have been shut off for some time. Should leakage occur, it will occur to a very small extent and will be trapped in the overlying rock layers. After completion of the CO2 injection, the reservoirs will be safely sealed.

How do the Porthos, Aramis and CO2next projects compare?

Porthos, Aramis and CO2next are all three projects focusing on CO₂ transport and storage. These projects complement each other and work together to achieve CO₂ capture, transport and storage in the Netherlands in and from 2026, with a focus on the port of Rotterdam and the North Sea. Porthos will transport 2.5 million tonnes of CO2 annually. The Porthos onshore pipeline is capable of transporting 10 million tonnes, so it can also supply CO₂ to future projects such as Aramis. The Porthos compressor station will be part of the Aramis CO2 transport infrastructure. It also forms the heart of the future CO₂ hub that CO2next will also be able to use. This terminal can receive liquid CO₂ by ship and deliver it to customers not connected to a pipeline.

The Aramis initiative requires several permits including one for the expansion of the Porthos compressor station. The draft permit was available for public consultation until 30 January 2025. All documents can be found at www.rvo.nl/aramis.

How is Porthos progressing now?

Implementation works for Porthos have started from spring 2024. The overview below gives an overall schedule of the work:

| January 2024 | Start of construction |

| First half 2024 – early 2026 | Onshore pipeline |

| First half 2024 – mid 2026 | Compressor station |

| First half 2024 – end 2025 | Cooling water intake building |

| First half 2025 – end 2025 | Platform |

| First half 2025 – end 2025 | Wells |

| Mid 2025 – end 2025 | Offshore pipeline |

| 2026 | Porthos system operational |

Will Porthos receive subsidy for this project?

Porthos receives financial support for the costs incurred in the preparation of the project and for the investment in the infrastructure. For the preparatory studies, Porthos received €1.2 million sub-subsidy from RVO in 2018 and €6.5 million subsidy from the European Commission in 2019. For the realisation of the infrastructure, Porthos received a €102 million grant from Brussels in 2021.

In spring 2021, Porthos’ customers were awarded SDE++ subsidy. They receive the subsidy to bridge any difference between the cost of the European Emissions Trading Scheme (ETS) and the total cost of capture, transport and storage. Because of the ETS system, it is expected that, in time, more and more will have to be paid for CO2 emissions. With this, it is very likely that our customers will receive much less, or perhaps no subsidy at all.

With this scheme, companies can contribute to achieving the Dutch Climate Agreement objectives while remaining competitive.

Get in touch!

Get in touch!